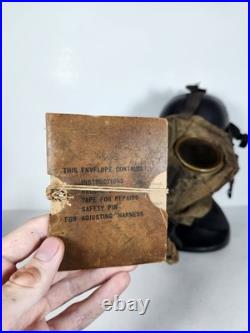

&####127482;&####127474; United States World War 1 Corrected English Type Box Respirator Size 3 Wide. The Corrected English Type Box Respirator was an improvement over the older failed American Small Box Respirator from early 1917, improving upon the terribly thin facepiece, lack of a valve bracket, and larger filters, with a thicker facepiece, better lenses, a greater hose and filter system, and a better carrier. This example of the Corrected English is quite an interesting one, entirely due to the filter it was issued with, being a Type J, though being manufactured by Landers Frary and Clark, a company introduced in 1862 in New England Connecticut. Prior to WWI, LF&C produced items such as cutlery and home appliances, though when WWI had started in July of 1914, they had to rework their products to fit military standards, this led to the production of Mess tins, Knives, Cavalry Swords, Canteen cups, and Gas mask items. LF&C had produced not only these strange Type L filters during the war, but they also produced removable lenses, Flory Washers (stiffeners for inlet tubes), and mouthpiece busings (device that prevented the rubber mouth piece of the inhalant tube from collapsing). According to a history of the company written by Barbara Ann Duggan in 1953, the company made the gas mask components at the facility that it opened in the State Trade School on South Stanley Street Duggan, Landers, Frary & Clark invented an important and life-saving development during World War I. It was reported that a new type of poisonous mustard gas was formulated by the Central Powers, and the existing gas masks were ineffective against it. Landers, Frary & Clark, along with the U. Army devised a new filter that was effective against the new gas, which is what you happen to see here. Landers, Frary, & Clark designed the necessary machinery for the production of the filters and five other New Britain manufacturers, P & F Corbin, North & Judd, Russell & Erwin, Hart & Cooley and the American Hosiery Company, assisted it in making and assembling the new filters. Together, the six companies produced 300,000 of them for immediate use.